INFORMATION ON PAINTING SYSTEMS

STEEL

The metal support used for the Metecno pre-painting is cold-rolled and galvanized steel for hot dipping of structural quality called S 280 GD + Z according to UNI EN 10147 standards.

The surface look used for pre-painting is established by UNI EN 10142 standards and is obtained through skinpassing (surface cold-rolling) the galvanized sheet after reducing the flowering of zinc or through the use of anti-cracking galvanized sheets.

Before the true painting, the galvanized and skinpassed strip undergoes a pre-treatment divided into various stages, whose purpose is eliminating any undesirable greasy deposits and oxides, and preparing the surface with inert salts that enhance the grip and adhesion of the paint coat.

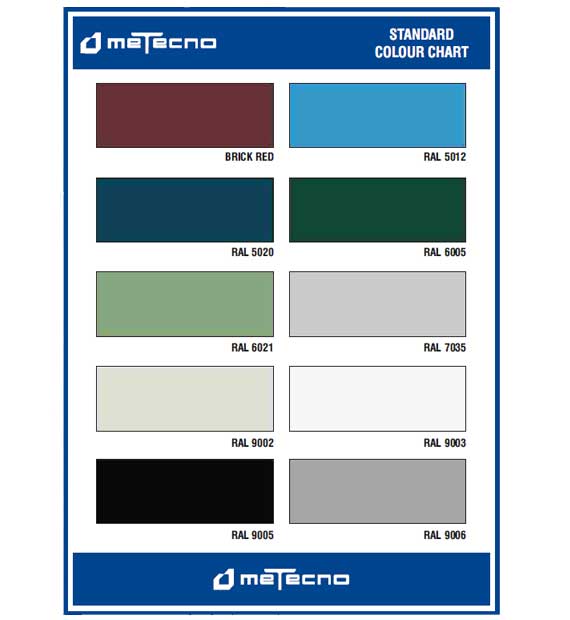

The pre-treated galvanized strip passes through the first painting head, which applies the first primer coat, and then through the first baking oven. In case of strips designed for the production of monolithic panels, a specific primer is necessary that guarantees the adhesion and grip of the polyurethane foam. When the strip passes through the second painting head and the second polymerizing oven, the final paint of the desired type and color is applied and baked.

Out of the existing paints, Metecno has selected three product lines, based on the opinion that this range is enough to face all kinds of weather conditions, from standard ones to the most aggressive ones.

- STANDARD system

It is a polyester-based system with an excellent stability when exposed to weather conditions and a good resistance to chemicals. - SUPER system

These are superpolyester-based and silicone-polyester systems. The resulting films are characterized by high resistance to the exposure to the sun, and have an excellent resistance to chalking and color changing. - PVdF system

These systems are based on polyvinyldenfluorurate mixed in variable ratios with acrylic resins. Since these films are highly chemical inert, the life of these coatings is particularly long when they are applied to building elements that are in touch with the external environment. The Metcno Coil Coating line can also manufacture Plastisol films, which are formed by a dispersion of PVC in a plasticizer; the thickness can vary between 100 and 200 microns. Plastisol films are suitable for particularly corroding environments, like iron metallurgic and chemical plants, but are mainly used in North European countries, where the insulation is lower than in the Mediterranean area. In fact, since these films are particularly sensitive to the UV rays, they easily chalk and change their color.

ALUMINIUM ALLOYS

In this case, the metal support used for the Metecno pre-painting is made of aluminum alloys of grade 3105 H18 or 3003 H18. The aluminum strip is also subject to a pre-treatment aimed at preparing the surface for the paint adhesion before painting, but using different chemicals from those used for steel. The strip is painted with the same methodology and process as those used for steel, and the painting cycles are the same as those described for steel, and also the behavior of the organic coatings is similar, considering the differences of the metal support.